OUR AIM

Turn your ideas to reality with our full fledged service capabilities. Equipped with the latest technologies and a passionate team, we would love to partner with you on your jounrey. No restrictions on creativity!

Facilities

Unleash your creativity!

The lab offers prominent facilities for machining, manufacturing, and developing ideas for products.

3-Axis CNC Milling Center

The CNC machine center is an advanced manufacturing machine tool that performs a wide range of machining operations with accuracy and a good-quality surface finish.

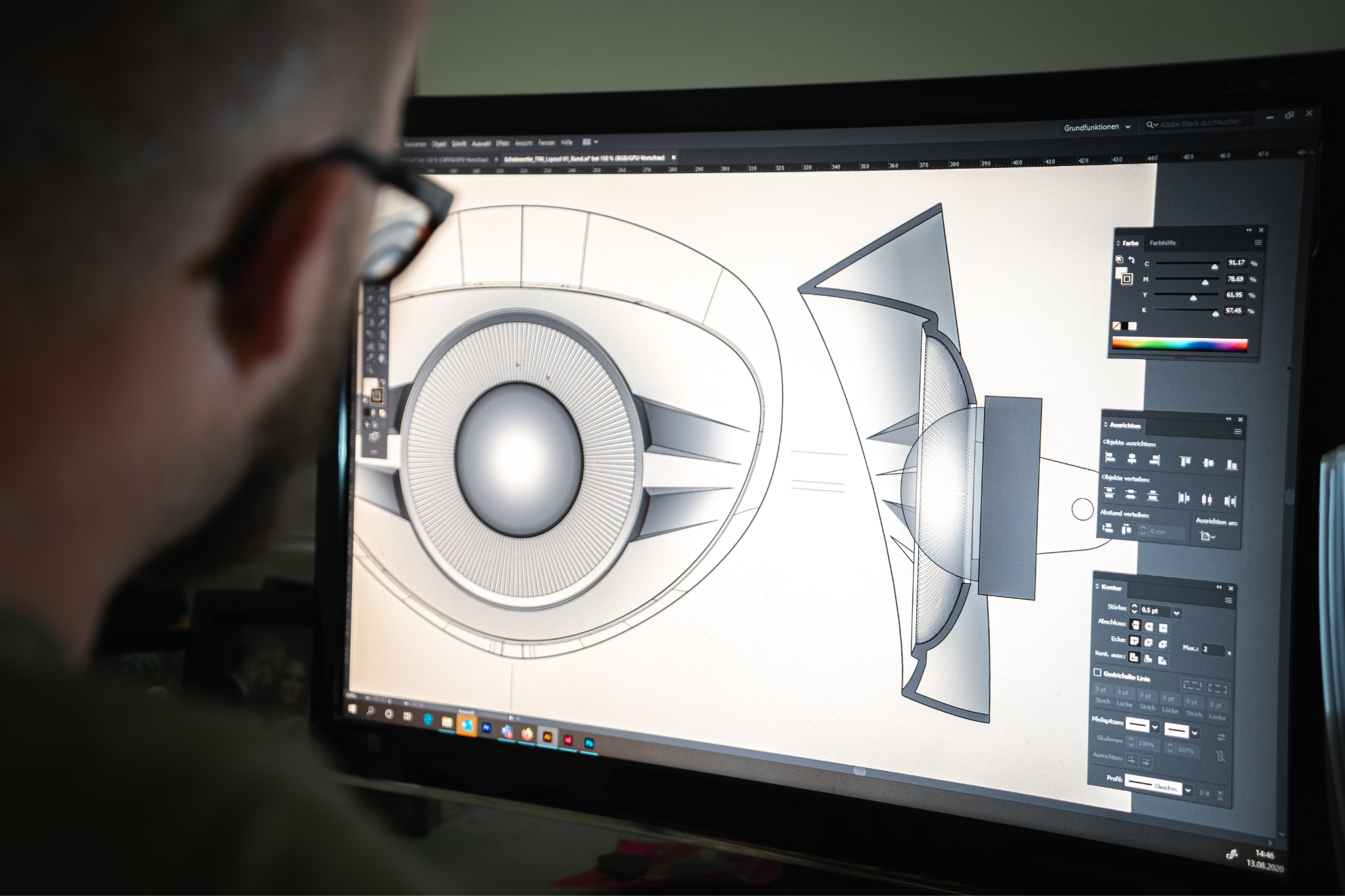

CAD Facilities

We utilize information technology (IT) in the Design process. A CAD system consists of IT hardware (H/W), specialized software (S/W) (depending on the particular area of application), and peripherals, which are quite specialized in certain applications.

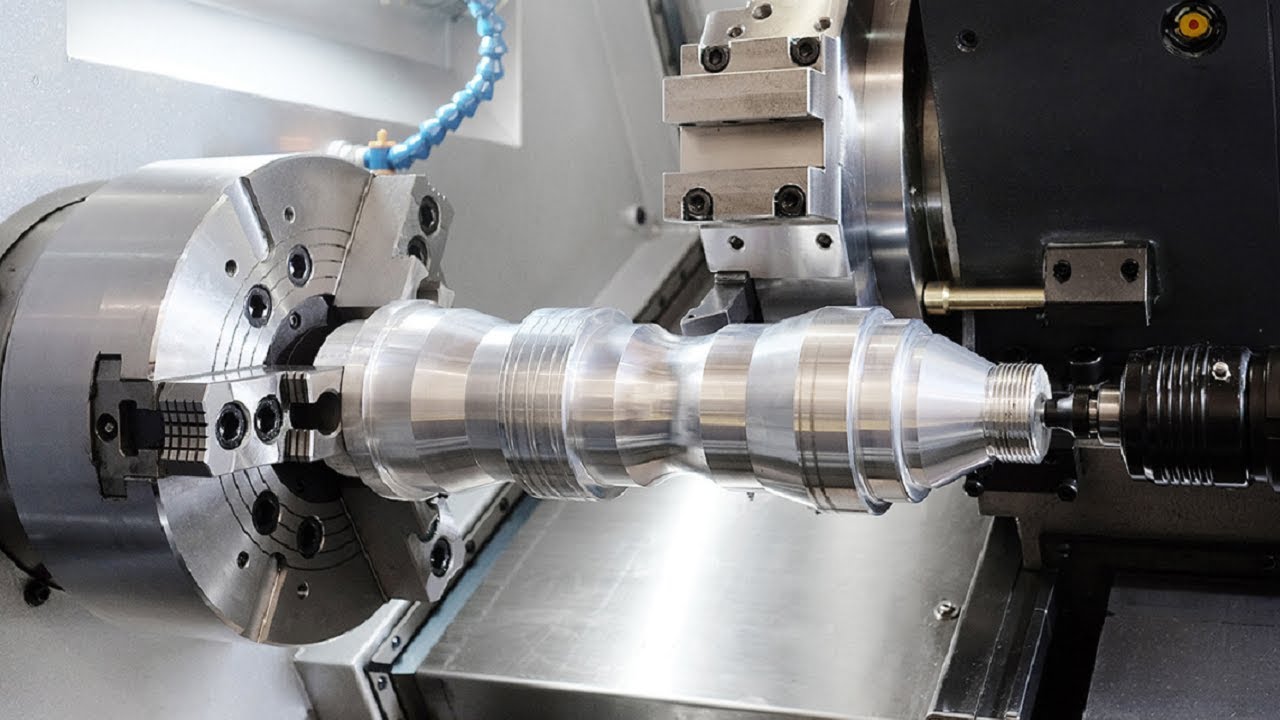

CNC Lathe

Computerized Numerical Control Lathe Machining Facilities are also available in the laboratory for the students, faculty members & in general product development.

Laser Beam Machining

Machining of brittle materials through laser for good finish & excellent precision. The lab boasts about its machining tools, which are capable of precision up to nano scale.

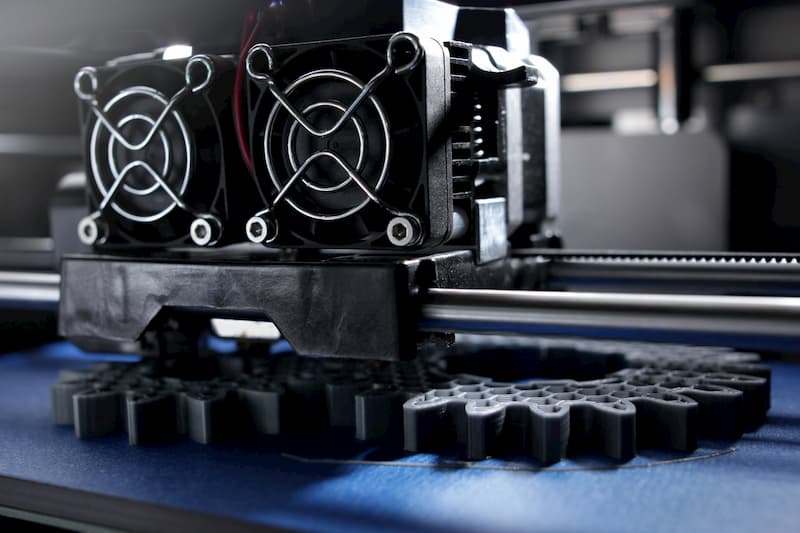

Rapid Prototyping

We have the facilities for the fastest fabrication of a physical part, model, or assembly using a 3D Computer-Aided Design. It’s done through varieties of printers available in the lab.

From HoDs desk

Professor Janakarajan Ramkumar, a faculty of ME, Material Science, & Design Programme at IIT Kanpur, specializes in the meticulous art of manufacturing at micro and nano levels. As coordinator of the micromachining lab, he and his team have pioneered the use of micro EDM milling, electrochemical milling, and laser micromachining to create groundbreaking products. Their focus extends beyond machining, embracing finishing processes like abrasive flow and magnetic abrasive finishing for optimal quality. Professor Ramkumar champions the transformation of design into reality, not just on paper, but in tangible prototypes through his “Imagineering Lab.” This unique space bridges the gap between concept and creation, empowering students and entrepreneurs to realize their ideas, be it medical devices or agricultural drones. His research continues to evolve, venturing into complex systems like application-based aerospace technology and non-intrusive medical devices, pushing the boundaries of what’s possible in the realm of micro and nano-scale manufacturing.

SALIENT FEATURES

- The laboratory provides a platform for students for hand on activity in the basic fabrication process of mechanical/ Electrical /electronic elements.

- From Tuesday to Friday, the Laboratory open from 9 a.m. to midnight. On Saturday, the lab remains open till 5 p.m. Sunday, and Monday will be the weekly off. Staff members will be available for help and guidance.

- At present basic lathe machine, basic milling machine, bench drilling machine, vacuum plastic forming machine, sheet metal cutting machine and bending machine, shearing machine, small grinder, buffing tools and grinder, drill machine, air compressor, welding machine, bench vices for metal fitting and woodwork activities, spray paint, all fitting and carpentry tool, making and measurement tools are also available.

- All basic machine equipment and hand tools will be provided to any student (B.Tech student having completed the TA201 Course) interested in trying out his/her ideas and fabricating machine parts and manufacturing.

- Efforts will be made to provide nuts, bolts, washers, screws, and fastener extract based on the specific requirement and availability of inventory.

- The infrastructure consists of modern machines like 3D printing metal plastic bench top CNC milling machine welding robots coordinate tracking measurement system in pipeline 3D scanner water jet cutting machine.