The focus is on developing and disseminating low-cost technologies to benefit rural populations, enhancing their livelihood options and self-sufficiency. Additionally, there is a goal to encourage innovation and creativity among students in technical institutions, engaging them in socially relevant projects. An ecosystem will be created to foster product and service innovation by connecting technology and engineering talent with grassroots institutions, end users, processors, and fabricators. Successful technologies will be commercialized and supported by an effective outreach program. A program will be developed to promote rural entrepreneurship and employment. Market studies will be conducted to identify technological gaps and available resources in various sectors. Finally, the RuTAG (Rural Technology Action Group) IIT Kanpur chapter has been initiated and nurtured in the region.

Agro and food processing | PRESERVATOR

Sabjikothi

An affordable storage unit that extends the shelf life of produce for 3 to 30 days without chemicals, preservatives, or refrigeration. Sabjikothi operates on low power consumption and can be solar-charged. Over 500 units have been deployed, resulting in a 30% increase in income for farmers and hawkers and a 40% reduction in wastage. Each unit mitigates approximately 1276.8 kg of carbon emissions, equivalent to cultivating 60 trees, providing a significant societal return on investment.

Advantages

- Extends shelf life of fruits and vegetables by 3-30 days.

- Affordable storage solution for small farmers, shopkeepers, and street hawkers.

- No chemicals, preservatives, or refrigeration required.

- Low power consumption (20 watts) and supports solar charging.

- Significant reduction in income loss and carbon emissions, increased sustainability.

Agro and food processing | ORGANIC FERTILIZER

Advantages

- Improved soil structure and water and nutrient retention.

- Reduces the need for synthetic fertilizers and pesticides.

- Less likely to cause plant damage compared to synthetic fertilizers.

- Limits carbon footprint due to minimal chemical inputs.

- Ehances Millets’ adaptability to climate change promotes resilience in agriculture.

Navyakosh highlights the unique advantages of organic fertilizers, including improved soil structure, reduced reliance on synthetic fertilizers and pesticides, and minimized plant damage. In another aspect, millet farming is gaining momentum as an environmentally friendly and economically viable agricultural practice.

Agro and food processing | ENHANCING VALUE

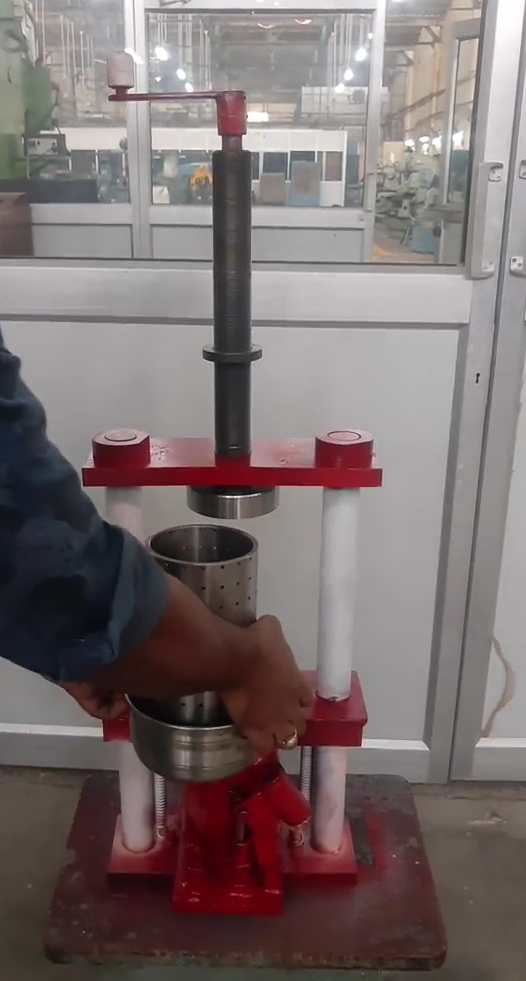

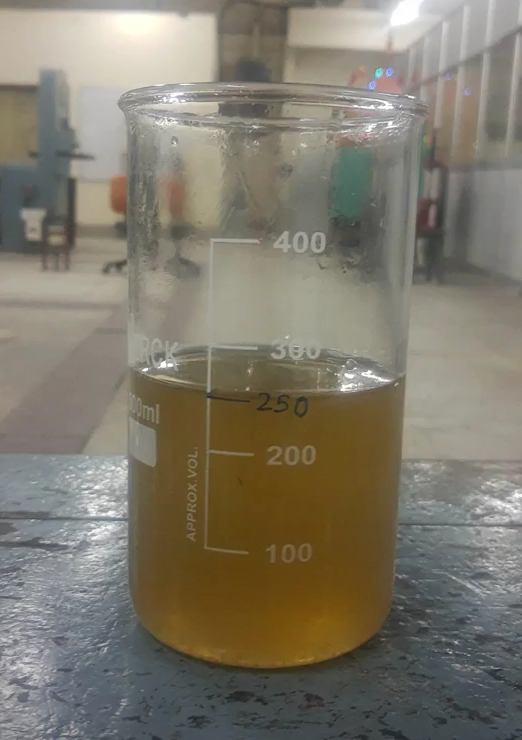

Cold Pressed Oil Expeller Machine

The Cold Pressed Oil Extraction Machine is a compact and efficient device used to extract oil from various oilseeds such as peanuts, coconut, sesame, soybean, and more. It consists of a main body, hydraulic jack, and plunger system. The oilseeds are fed into the chamber and crushed by the downward force of the plunger rod.

The oil then flows out through holes in a stainless-steel cylinder. The machine offers high-quality oil extraction with minimal energy cost. Additionally, there is a screw oil press setup designed for extracting edible oil from peanuts. Both setups are user-friendly and suitable for daily wage employees and households, preserving the natural flavors and ingredients of the extracted oil.

Advantages

- Versatile extraction: Extracts oil from a wide range of oilseeds.

- Efficient and cost-effective: High yield with minimal energy cost.

- High-quality oil: Preserves natural flavors and nutrients.

- User-friendly design: Compact and easy to operate.

- Reduced waste and environmental impact: Minimizes leftover material and eliminates chemicals.

Agro and food processing | OPTIMIZATION IN PROCESSING

Integrated Processing Machine

•Improvement in efficiency at the point of procurement can significantly bring down costs.

•Lack of infrastructure like shed and dryer is an issue.

•Machine can sort, clean and Dry, at the procurement center

•Sorting by uniform specification in term of percentage.

•Organic, mature, shrunken grains are removed by passing of air.

•By passing hot dry air with suitable humidity the moisture content is absorbed from grain.

Agro and food processing | SMART AGRICULTURE

Krishi Mandi Data Driven AI Optimised Agri-Supply Chain

The Krishi Mandi App is an innovative solution that addresses the challenges faced by farmers in India. By leveraging mobile technology, the app enables farmers to communicate directly with mandi traders, eliminating the need for intermediaries and reducing logistics costs.

The app also offers an AI-optimized e-commerce platform, empowering farmers to increase their income by 20-33% while providing customers with a 16% discount on farm-to-business transactions. Additionally, AI technology predicts crop yield and quality, bridging the gap between farmers and consumers and promoting organic products.

Advantages:

- Improved access to information and technology for small-scale farmers.

- Mobile phone-based solution aids in farm management and agricultural productivity.

- Connectivity with mandi traders through the Krishi Mandi App.

- AI-optimized e-commerce platform reduces middleman interference and enhances farmer income.

- AI-trained application predicts crop yield, quality, and rate, benefiting farmers and consumers.

Agro and food processing

Grain Collection & Packing system

The grain filler machine is specifically designed for filling grain in the agriculture and food industry. It consists of a hopper, weighing device, and an upper entrance to facilitate work progress while minimizing material loss. To address the labor-intensive task of filling grain during harvest, a manually driven grain filling machine was developed.

It has a filling capacity of approximately 100 kg of grain every five minutes, making it highly efficient and causing minimal grain damage. The machine operates without the need for power and meets the high demand for grain filling in the local farming and retail sectors, reducing waste and storage time.

Advantages:

- Efficient filling capacity of 100 kg grain every five minutes.

- Minimizes grain damage during the filling process.

- Operates manually, eliminating the need for power.

- Meets the high demand for grain filling in agriculture and food industries.

- Reduces wastage and storage time in farming and retail sectors.

Agro and food processing | PROCESSING

Ground Nut Separator Machine

To address the laborious task of separating groundnuts from their roots, a manually operated power groundnut separating machine was developed.

The machine offers a cost-effective solution that is lightweight, doesn’t require electricity, and is simple to use, eliminating the need for skilled labor. The prototype not only increases the efficiency and efficacy of the separation process but also reduces harvesting time and waste. It has the potential to create job opportunities in rural areas, contributing to economic development and improved livelihoods for farmers.

Advantages:

- Cost-effective and lightweight solution for groundnut separation.

- Operates without electricity, reducing energy dependency and costs.

- Simple to use, eliminating the need for skilled labor.

- Increases efficiency and efficacy of the groundnut separation process.

- Reduces harvesting time and waste, improving productivity and sustainability.

Agro and food processing

Pineapple Peeler

The objective was to develop a pineapple-peeling machine to address the challenges faced by farmers and reduce the time required for peeling pineapples. The designed machine automates the peeling process, aiming to improve the efficiency of small businesses, farmers, and individuals. Traditional pineapple peeling methods are time-consuming and labor-intensive, resulting in wastage.

The manually operated, lightweight pineapple peeling machine was designed to peel approximately 30 to 40 kg of pineapple per hour. Its versatile design can handle various types and sizes of pineapples while causing minimal fruit damage. The machine caters to the high demand for pineapple peeling in both commercial and domestic juice extraction operations.

Advantages:

- Automates and speeds up the pineapple peeling process.

- Reduces time and effort required for peeling pineapples.

- Minimizes fruit wastage and decay caused by traditional methods.

- Manually operated, lightweight design for easy handling and mobility.

- Versatile machine suitable for different types and sizes of pineapples.

Stone Apple/ Bael Cutter Tool

The manual de-shelling of Bael fruit is currently the predominant method, but it has limitations in terms of efficiency and quality. To address this, a new machine has been designed for cutting and slicing Bael fruit, simplifying the process and improving productivity.

This technology enables quick and easy chopping and slicing of 20 fruits in just 10 minutes, with adjustable slice thickness. The machine ensures ease of use, storage, preservation, and maintenance, enhancing the efficiency and application value of Bael fruit.

Lemon Plucking Setup

The farmers find manual plucking to be challenging in the absence of

effective technology. Unable to use the entire crop of lemons because of

their limited shelf life. As a result, a lot of the gathered fruits can spoil

and go to waste. A Lime harvester has been developed for harvesting

limes. It is easy to push the lime harvester in dense canopy of the plant.

The fruit is held in the hook, harvested and collected in the box while

pulling the harvester.

The developed lime harvester contains fruit catching unit, fruit

collection mouth, conveyance pipe and collection chamber. The

developed lime harvester is manually operated, lightweight, very

effective lemon-plucking tool with minimal harm to the lemon. The

machine operates without electricity and can pick 40 to 50 kg of lemons

in an hour.

Lady Finger Plucking Tool

As there is no effective equipment for plucking, farmers must perform

difficult and time-consuming labour. As a result, a lot of the gathered

ladyfinger can spoil and go to waste. In the process of plucking, it

irritates the hand. For this, we developed a manually operated,

lightweight ladyfinger plucking tool that is highly effective and causes

little ladyfinger harm. The tool operates without electricity and can

harvest 40–50 kg of produce in an hour. There is a high demand for

picking ladyfingers off plants, which also reduces harvesting time,

waste, and labour costs.

Increasing life of horseshoes

Horseshoes are fabricated products used to protect horse hooves. They are typically nailed or glued to the hooves and come in various shapes and materials. Steel and aluminum are popular choices. Horseshoes can affect a horse’s gait and may be customized for corrective purposes or to enhance natural movement. Specialized horseshoes are used for racing horses and those with weak feet or legs. In Uttar Pradesh, a prototype has been created using high carbon steel, offering an alternative to the current technique.

Ground Nut Separator Portable Setup

This Ground Nut Separator Portable Setup separates peanut from plant

root when processing crushed nuts. Workers often performed ground

nut separation manually. For instance, it takes 5 members for 5-7 days

to finish one hectare. Furthermore, we can separate a hectare of ground

nuts with this technique in two to three days. Our machine can be used

by two members at once. Ground Nut Separator Portable Setup is

lightweight, manageable, power-free, economical, and only requires one

paddle and one person to operate, according to the present design. The

potential effects include the creation of rural jobs, the expansion of

rural small businesses, and the reduction of product loss.

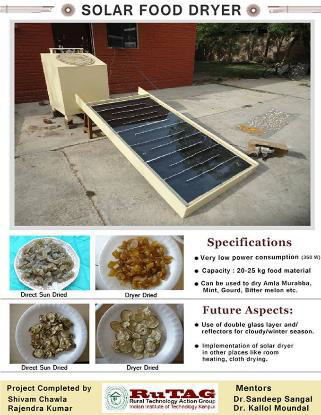

Solar Food Dryer

Drying is crucial for post-harvest food preservation, and solar dryers offer a sustainable solution. We developed a Zero Energy Solar Thermal Dryer that effectively dries agricultural products. The dryer utilizes a Flat Bed Aluminium-based Collector covered with glass to collect solar energy. Hot air from the collector passes over the green load in a well-insulated drying chamber with trays. A chimney with a turbo-ventilator removes damp air, and the dryer operates without electricity.

The inexpensive and low-maintenance dryer achieves temperatures between 45 and 65°C, ensuring effective solar energy use without fruit discoloration. It is suitable for small-scale food processing facilities in rural areas, improving crop quality and reducing losses.

Pomegranate Deseeder Machine

The pomegranate deseeding machine aims to increase production, reduce labor, ensure hygiene, and cater to small businesses with limited budgets. The lightweight, electric or battery-operated setup efficiently extracts seeds from 25 to 30 kg of pomegranates per hour. The prototype is highly sought after for household and juice extraction businesses, reducing harvesting time and waste while preserving seed quality.